Thermal Mass and Insulation, Local Conditions Dictate the Function

Notes from SouthWoods

Advanced Permaculture Series

Thermal Mass and

Insulation, Local Conditions Dictate the Function.

Building

strategies in changing climates vary based on the biomic tendencies of the

region. Cold or Hot regions also

have sub regions of precipitation, wind, and landforms. Speaking of cold

climate strategies, principles and solutions still apply; its the various materials and conditions on site

that dictate the implementation. In mountainous and higher latitudes, the

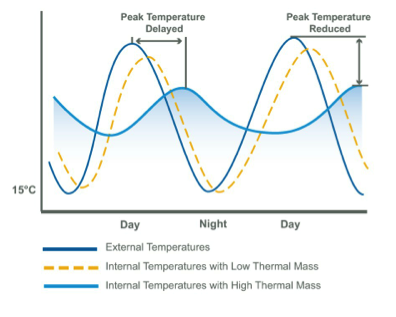

cold can be relentless. Unlike a Desert, the daytime and nighttime temperatures

(Diurnal Temperature Variations) may not fluctuate enough to use thermal mass

to buffer the changes, such as with adobe or earth bag homes. The continuous lower temperatures

quickly transfer into the thermal mass, and in time, begin to absorb the heat

within the structure. Large log or

stone homes, which keep cool in summer as the temperatures cool at night and rise

during the day, lose their benefit in a cold climate. This relationship between

structure and function needs serious consideration when planning a natural

building. Should the thermal mass be inside? Such as with a rocket stove

fireplace and insolation in the exterior walls. Or, should the thermal mass be

on the outside to moderate the diurnal temperature differential of hot days and

cold nights? There would seem to be hybrid combinations for every climate. How

dense and how thick should the walls be in each situation? What is the strategy

of isolation and mass density to achieve the best efficiency?

Building

strategies in changing climates vary based on the biomic tendencies of the

region. Cold or Hot regions also

have sub regions of precipitation, wind, and landforms. Speaking of cold

climate strategies, principles and solutions still apply; its the various materials and conditions on site

that dictate the implementation. In mountainous and higher latitudes, the

cold can be relentless. Unlike a Desert, the daytime and nighttime temperatures

(Diurnal Temperature Variations) may not fluctuate enough to use thermal mass

to buffer the changes, such as with adobe or earth bag homes. The continuous lower temperatures

quickly transfer into the thermal mass, and in time, begin to absorb the heat

within the structure. Large log or

stone homes, which keep cool in summer as the temperatures cool at night and rise

during the day, lose their benefit in a cold climate. This relationship between

structure and function needs serious consideration when planning a natural

building. Should the thermal mass be inside? Such as with a rocket stove

fireplace and insolation in the exterior walls. Or, should the thermal mass be

on the outside to moderate the diurnal temperature differential of hot days and

cold nights? There would seem to be hybrid combinations for every climate. How

dense and how thick should the walls be in each situation? What is the strategy

of isolation and mass density to achieve the best efficiency? Insulation is used much more in colder

climates to abate the infusion of extreme temperatures into a structure.

Homes have thick walls and roofs filled with millions of airlocks cells that

moderate the temperature change between the two sides. Double and triple pane

glass is used in the windows to again add a barrier to temperature change

between the solid materials. Air and gases are used between the panes of glass,

much like a thermos bottle, which uses a vacuum chamber between the outer wall

and inner container filled with hot liquid. Reducing the energy transfer on the

edges increases the energy storage capacity of the space.

Insulation is used much more in colder

climates to abate the infusion of extreme temperatures into a structure.

Homes have thick walls and roofs filled with millions of airlocks cells that

moderate the temperature change between the two sides. Double and triple pane

glass is used in the windows to again add a barrier to temperature change

between the solid materials. Air and gases are used between the panes of glass,

much like a thermos bottle, which uses a vacuum chamber between the outer wall

and inner container filled with hot liquid. Reducing the energy transfer on the

edges increases the energy storage capacity of the space.

So we have two principles working in a cold

climate. There is the thermal mass of

the structure including the air or water within the structure and the degree of insulation, which buffers the

temperature changes across the layers of the edge or surface.

While working in Haiti

I found that the dense block buildings a cool place in the day, but frigid each

night. As a result, I lay on top of my 0ºF Polarguard sleeping bag in the

sweltering temps of the late evening and around 2 AM, when the cold woke me up,

I crawled inside the warmed bag. Part of the solution might be integrating our

own habits with the dynamics of the built environment, just as we do the

natural environment. Inside our homes we can insulate ourselves with fingerless

gloves, and a sweater, or stocking cap. This is much easier than another cord

of firewood or gallons of fuel oil. Start with zone “0”. Cultural adaptation is

much easier than mechanical constructs.

Organisms use respiration and change their insulation

depending on conditions. The dynamic relationship between thermal mass and

insulation is optimized when managed as needed (warm blooded), rather than

being a static and passive system (cold blooded). Low temperatures extract energy from sources of heat. Cold

climate systems slow that heat energy loss and minimize calories used to

replace it.

Phase Change Materials

Phase

change materials (PCM) are special materials for increasing the heat storage capacity without adding extra weight to the

structure. Here the phase change is used for energy storage. As the temperature increases, the material

changes phase from solid to liquid and during the chemical process energy is

absorbed. This way the room temperature will be lower. Later when the

temperature decreases, the material changes phase from liquid to solid and

dissipates the heat. This energy is expended and removed from the room through

night-time warming of the air. Ventilation can be increased with a fan and the air

blown directly on the phase change mass. The temperature of the PCM itself

remains constant during the reactions.

For building

applications, the phase change should take place near the comfort temperatures,

between 18 and 25°C. The phase change point depends on the type of material

applied. If this temperature is too low, the heat storage capacity is exhausted

too early, if it is high, starts too late and the influence is small.

Microencapsulated

PCM (e.g. paraffin) can be mixed to interior plaster, wallboard panels or

aerated cement blocks and applied in the building without any special measures,

just like conventional materials (Figure 63). Encapsulation is important, as

the PCM must not be in direct contact with other materials to avoid damages due

to the “melting” process. 30 mm plaster

coating with 30 % PCM has a heat storage capacity equivalent to 180 mm concrete

(http://www.new4old.eu/guidelines/D3_Part2_H2.html

Comments